Your shopping cart is empty!

Choosing a DC Motor

We have seen many makers face difficulties in choosing the right motor for their mobile robots as well as automation projects. Many of them are not from a mechanical engineering background hence the calculation of torque, the gear ratio and motor power appear so unfamiliar to them.

This article summarized the 6 most fundamental knowledge about DC motors that hopefully would be able to help the newbies to select the right one for their projects.

1. AC MOTOR AND DC MOTOR

It is good to know that you have an option to use the AC motor if it fits your application.

| AC MOTOR | DC MOTOR | |

| Power Source | Powered by AC power source | Powered by batteries or DC power source |

| Control | Difficult to control the speed and direction | Easier to control the speed and direction |

| Size | Usually in bigger size | The smallest DC motor can be as small as your fingertip |

| Application | Suitable for stationary applications or where longer operating time is required such as fan and sewing machine. | Suitable for mobile applications such as cars where we are unable to get AC power sources. |

Conclusion: If you are building a project that requires battery and/ or mobile operation (such as a mobile robot or drone), then DC motor is the best option.

2. TYPE OF DC MOTOR

There is numerous type of DC motor in the market but the most commonly used are the brush motor, stepper motor and servo motor. Let’s have a quick glance at the major differences between these DC motors from the table below.

BRUSH MOTOR |  STEPPER MOTOR |  SERVO MOTOR | |

| Character | The most common and easiest to use. It will rotate continuously if power is supplied. | Stepper motor is a motor that moves in discrete steps, one step at a time. | By definition, a servo motor is a motor with closed loop position/speed control. |

| Control | There are 2 wires from the motor, connect one wire to the “+” terminal of the battery and another wire to the “-” terminal. Reverse the polarity will cause the motor to rotate in the opposite direction. If you wish to control the motor’s speed and direction in a more efficient way, you need an external motor driver. | There are 2 types: bipolar (4 wires) and unipolar (6 wires). You are unable to connect these wires directly to a battery, instead, you will need a stepper driver to drive the stepper motor. | Usually, there will be more than 2 wires from the servo motor. The main 2 wires (usually thicker) are to provide the power source and the remaining wires are to provide the position signal to the controller. |

| Application | For general applications such as a mobile robot where you need to move forward and backward or pull a string to a certain limit. The accuracy of the rotation is not critical. | It can achieve very precise positioning. For this reason, stepper motors are recommended for precision motion control applications such as 3D printer machines. | RC servo is used to control the engine throttle of a RC car. While the industrial servo is used to drive the robot arm. In both cases, real-time monitoring in position and direction of the motor rotation is critical. |

| Example |

Robot vacuum cleaner

Car’s power window |

3D printer

Printer |

Industrial robot arm Humanoid robot |

3. WHAT IS THE GEARHEAD AND GEAR RATIO?

Before we proceed, it is good to learn some basic knowledge about the gearhead attached to a motor.

Ordinary DC brush motors without gearheads produce very high RPM and very little torque. You can see the video below, although the motor rotates at a very high speed, it stops immediately when we try to touch it using our fingertip, which means the torque is very low.

To solve the problem, we attach a gearhead at the same motor to reduce the speed of the motor and at the same time increase its torque. As you can see from the video below, the motor rotates slower and we are unable to stop it using our fingers.

How does it work? From the video above, you can see that the speed of the first gear rotates very fast and it gets slower by the gears and finally produced an output that rotates slower and produces higher torque at the same time. You can learn in detail how the gear train works: https://www.wikihow.com/Determine-Gear-Ratio

4. Torque and RPM

Torque and RPM (revolution per minute) are the most important and common specifications of the DC motor. We need to estimate the torque and RPM required for our application to decide which motor to use.

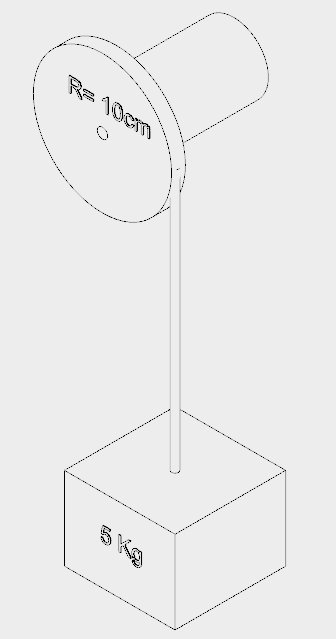

Torque is a measure of how much force we need to rotate an object. The common units of torque are “N.m”, “oz-in” and “kgf.cm”.

Torque = Force x Distance

From the example above, the minimum torque required to at least hold the 5Kg’s load is

Torque = Mass of the load (in Newton) x Radius of the pulley (in meter)

= 5 x 9.81 x 0.1

= 4.905 N.m

RPM is a common unit to measure the speed of a rotating object. How many rotations it can achieve in 1 minute (60 seconds). Assuming the motor is rotating at a speed of 10RPM, means the pulley is able to rotate 10 x 2 ? R = 10 x 2 ? (0.1) = 6.28 meters of string in 60 seconds.

5. How to calculate torque and RPM for a Mobile Robot?

Calculating the torque and RPM required for a pulley system is straightforward, but how about a mobile robot where you have more parameters to consider?

Image Credit: DF Automation

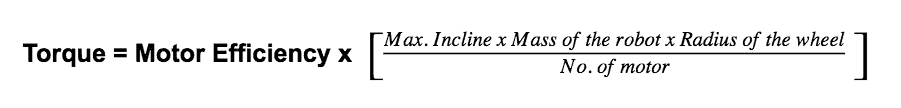

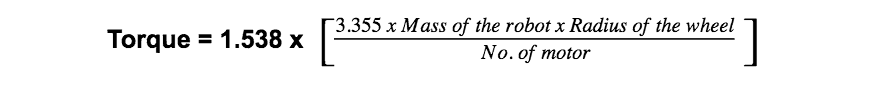

We need to consider the number of motors we use, the motor efficiency, the size of the wheel, the robot’s acceleration and the incline degree. Please refer to the equation below to calculate the motor's torque of a mobile robot.

To make life easier, I have simplified the formula by giving some assumptions about where most of the mobile robots should applied:

Where you only need to key in the total mass of your robot in Kg, the radius of the wheel you use at your motor in meters and the number of motors on your robot.

*Note: Most of the motor efficiency in the market is 65% and I assumed the maximum incline required for your robot is 20° which should be sufficient to move through some small bumps. If you wish to change the parameters, you can use the motor sizing tool provided by RobotShop.

The answer from the above equation will be in Newton meter (Nm), which you can convert to other units using the online converter.

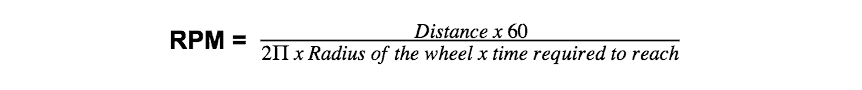

To calculate the RPM required by the motor, you need to apply this formula.

*Note: Distance and radius in meter (m) and time in second (s).

6. Safety Factor

In engineering design, we usually apply a reasonable safety factor to compensate for unknown circumstances in the real-world environment such as the friction between the wheel and the ground.

A safety factor of 1.5 means we are using a 50% larger motor than our original calculation. The larger the safety factor the safer it is for the selected motors to work for your project. However, it also means your design is not “efficient”. A bigger motor also means a more expensive and higher load on your robot which will consume more energy. Imagine you are using a super huge truck just to carry a few basketballs, it doesn’t make sense at all. In short, you need to provide an optimum safety factor for your motor selection.

From my personal experience, a safety factor between 1.3- 1.8 is considered a safe play provided there is no mistake in your calculation. Also to take note that the motor’s weight is within your weight constraint. Now, you should have your calculated's torque and RPM ready and you may start to choose the motor you want to use. Again, I have personal experience on how painful it is to compare the motors’ specification page by page, the missing info and the ununiform of the motor specs, all of these are such a time-consuming and dull process. So I have spent some time listing down all the DC motors Cytron is selling according to the motor weight, torque and RPM. Hope it helps.

Final Tips

If, somehow your system is uncommon and you are unable to apply the equations given above to estimate the torque and RPM. Don’t worry, you still can use your common sense to ‘guess’. Yes, guessing is the last thing you can do and it is not something wrong at all as long as your project is able to work.

Bigger motors produce higher power, either high torque or higher speed or both.

We need to start ‘guessing’ for the speed you require because it is easier. Let me give you some guides.

The drone’s motors spin at >10K RPM

Volleyball’s feeder works at 1000-2000 RPM

Conveyor belt’s motor usually rotates at 60-20 RPM

Typically, RPM > 10K is considered extremely fast, 500- 50 RPM is the normal range of speed for most projects.

Once you get the RPM, then you can choose the motor size and weight. In most cases, the motor size and weight are one of the important specifications to be considered too. I would suggest you go for the biggest permission size to give more allowance to the motor torque.

I hope this article helps. In case you have any questions or find any mistakes in the article, please feel free to leave your message below.

International

International Singapore

Singapore Malaysia

Malaysia Thailand

Thailand Vietnam

Vietnam