Most people do not know which DC motor is suitable for their mini projects, robot projects, and other automation projects. Usually, we will just use the trial and error method to find out which DC motor is the most suitable for our project. So let’s figure it out how to properly choose the most suitable DC motor for your project.

STEP 1: Why do you need a DC motor?

- For a mobile robot?

- For a pulley?

- For a conveyor belt system?

STEP 2: Which type of DC motor do you want to use?

- DC brush motor?

- DC brushless motor?

- Servo motor?

- Stepper motor?

- Linear motor?

- Power window motor?

Comparison of the motor:

| DC MOTOR | EXAMPLE OF APPLICATION | ANGLE | WHEEL | PRICE |

| DC geared motor | Mobile robot, pulley, conveyor belt, lifting system. | No | Yes | Rm40- Rm206 |

| Servo motor | Control position | Yes(0-180) | No | RM 26 - Rm111 |

| Stepper motor | Rotation stage | Yes (360) | Yes | Rm 26.50 |

| Linear motor | sliding door, | No | No | Rm 349.80 |

| Power window motor | Lifting, pulley, mobile robot. | No | Yes | Rm 33.92 |

The price shown above is the price of the DC motors sold by Cytron.

You can see more detail about our DC motors here.

STEP 3: What is the specification you need to know before you buy a DC motor?

- Maximum Torque.

- Maximum Weight.

- Maximum Voltage.

- Maximum Current.

- Maximum Speed.

- The diameter of the wheel used.

You can click here for more details about our motor specifications.

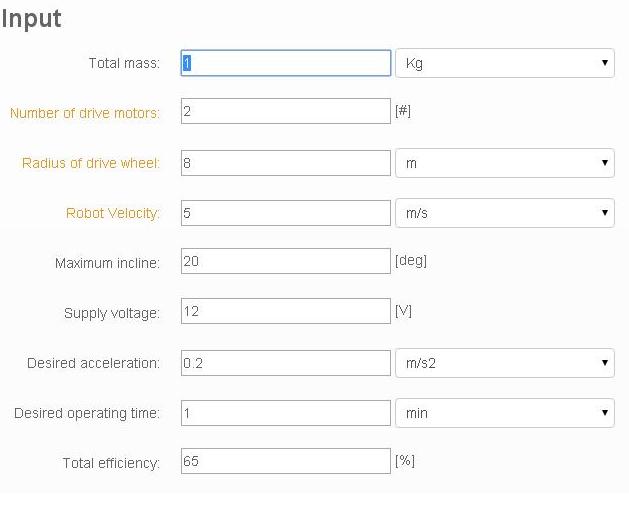

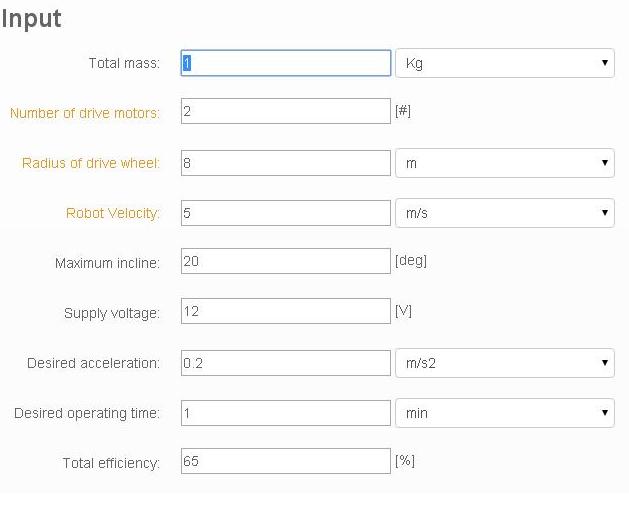

You can try using any online calculator to find out which motor got the best specifications for your projects. One example of the online calculator:

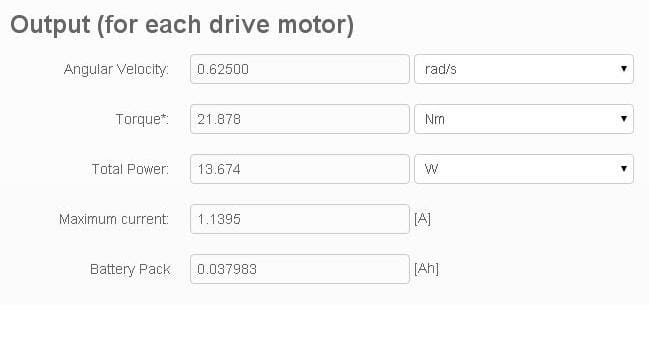

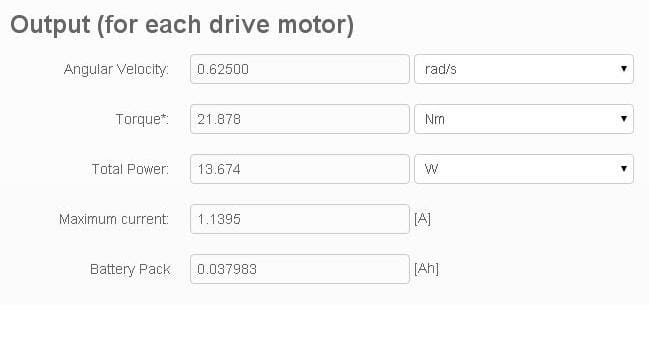

STEP 4: Where do you want to put your load?

Example:

STEP 5: Convert the torque given by the specification of the DC motor to kg/cm.

Most of the DC motor specifications on the market only show the torque, current, and voltage of the DC motor, not the weight that the motor can support. My suggestion is to convert the N.m to kg/cm with an online calculator first to make everything easier.

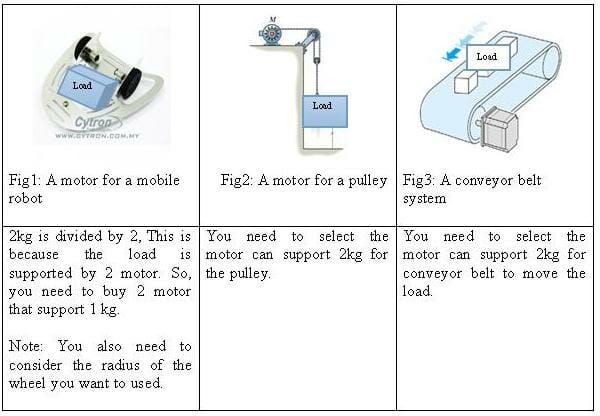

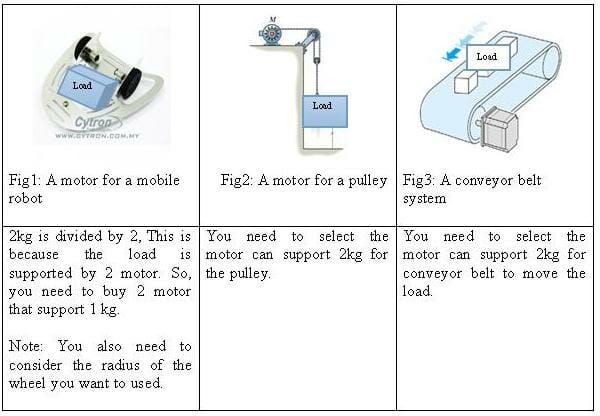

Question: What is the meaning of kg/cm?

Answer: We want to know the load that the motor can support (in kg) if we use a turning axis of 1cm radius.

Note: As the turning axis' radius is increased, the weight can be supported decreases.

The picture below explaining about the meaning of the kg/cm related to the motor.

Step 6: What else do we need other than DC motor?

MOTOR DRIVER

If you want to control the direction and speed of the DC motor.

Question: Why do we need a DC motor driver?

Answer: Because the current and voltage from a microcontroller are tiny.

Note: Every DC motor driver is different. So, you will need to read the user manual of the DC motor driver carefully before you buy and use it. You can see more detail about our DC motor drivers here.

ENCODER

Encoders are sensors that identify the speed of rotation, angle of rotation, direction of rotation, and even the position of the shaft. They can be applied on a robot arm’s joint, mobile robot, conveyor system, or even a printing machine.

POWER SUPPLY

Power supply supplies a current and voltage to the system. You need to choose your battery according to your DC motor driver.

Note: You can click here for more details about our power supply.

STEP 7: Which DC motor driver is suitable for your DC motor?

Most students only know how to control DC motors with the L293D. But the problem is you will still need to construct the power supply and circuit. The current is also limited if you use L293D.

The specification of the DC motor driver you need to check:

- Maximum current support for the DC motor.

- The range of voltage is supported by the DC motor.

2 types of Cytron's DC motor drivers:

- DC Motor driver

Can control the direction and speed of the DC motor with high current.

- Smart Drive DC Motor Driver

The Smart Drive DC Motor Driver is much easier to use, just plug and play! You only need to choose your RC controller and then you can control your robot even without a microcontroller. It has the capability to accept RC (Radio Control) signals for mix mode drive, analog voltage from the potentiometer, PWM from the microcontroller, and can even be controlled via UART commands. These operation modes can be configured via the onboard DIP switch (commonly configurations are printed at the back of the board). The MOSFETs switch at 16KHz for quiet operation. With the onboard temperature sensor, this smart driver is also able to limit the output current stage by stage to prevent itself from overheating and burning!

STEP 8: Choose the suitable encoder for your DC motor if necessary.

For your information, Cytron also sells DC motors with encoders attached to make it easier for you to buy them.

You can refer here to see our DC motors with encoders and without.

Note: This tutorial just covers the basic elements of how to choose your suitable motor. If you want to know more about motor selection, there are so many explanations on the internet you can search and read.

If you have a further inquiry about this tutorial, please post it in our technical forum here as we seldom check the comment section on the tutorial site.

Thank You, I hope this tutorial will help you to choose your DC motor. :-)

REFERENCES

Torque kgcm

BUY

International

International Singapore

Singapore Malaysia

Malaysia Thailand

Thailand Vietnam

Vietnam